Metalworking Fluids

Castrol Industrial is the industry leader in innovative, performance-driven neat / soluble / semi-synthetic / synthetic metalworking fluids.

Castrol provides a wide range of metalworking fluids, meeting the demands of the most challenging manufacturing operations and difficult materials. This is why LubeCon exclusively distributes Castrol branded metalworking fluids.

Metalworking Fluids

Solubles/Semi-Synthetics

Castrol’s metalworking fluids are completely free of chlorinated paraffin. Castrol Industrial North America is the industry forerunner, having removed them from all our products in 2011 to eliminate this risk for our customers.

Please consult your LubeCon sales representative for specific recommendations on machining applications and materials.

Y = Suitable –varies by application (refer to PDS) N = Not Suitable C = Consult Castrol Representative prior to use

*Note: Use of high oil-containing coolants on cast iron can lead to smut w/o proper filtration.

Metalworking Fluids

Hysol MB Series

Hysol MB series coolants are high- performing, long- life and low usage coolants for ferrous and aluminum machining. These lubricants offer multi-metal compatibility, excellent tramp oil rejection, and superior bio-stability for extended sump life. Operator acceptance is extremely high, as these fluids form stable, translucent emulsions with a very mild odor. Several grades are available to match the varying degrees of performance required.

Outstanding All-Around Performance

Hysol MB series metalworking fluids are globally popular due to their excellent overall performance and value. In one case study at a shop producing parts for the aerospace and defense markets, Hysol MB 50 provided excellent performance in key areas that most manufacturers desire, including:

- Long sump life – Hysol MB 50 doubled sump life

- Cleanliness – sump, machine, and windows were much cleaner

- No staining of parts – Hysol MB 50 eliminated staining of multi-metal parts

- Excellent machining – scrap and rework was greatly reduced

- Versatility – Hysol MB 50 was effective on all metals and operations (including titanium, Inconel, stainless steel, and aluminum)

Low Usage

Hysol MB series metalworking fluids form tight emulsions that resist carry-out on parts and stay in solution much longer than conventional semi-synthetic coolants, often generating 20-30+% lower usage. Customers often note the low amount of make-up coolant needed after charge-up, although we recommend small regular additions to ensure that additives remain at the correct levels.

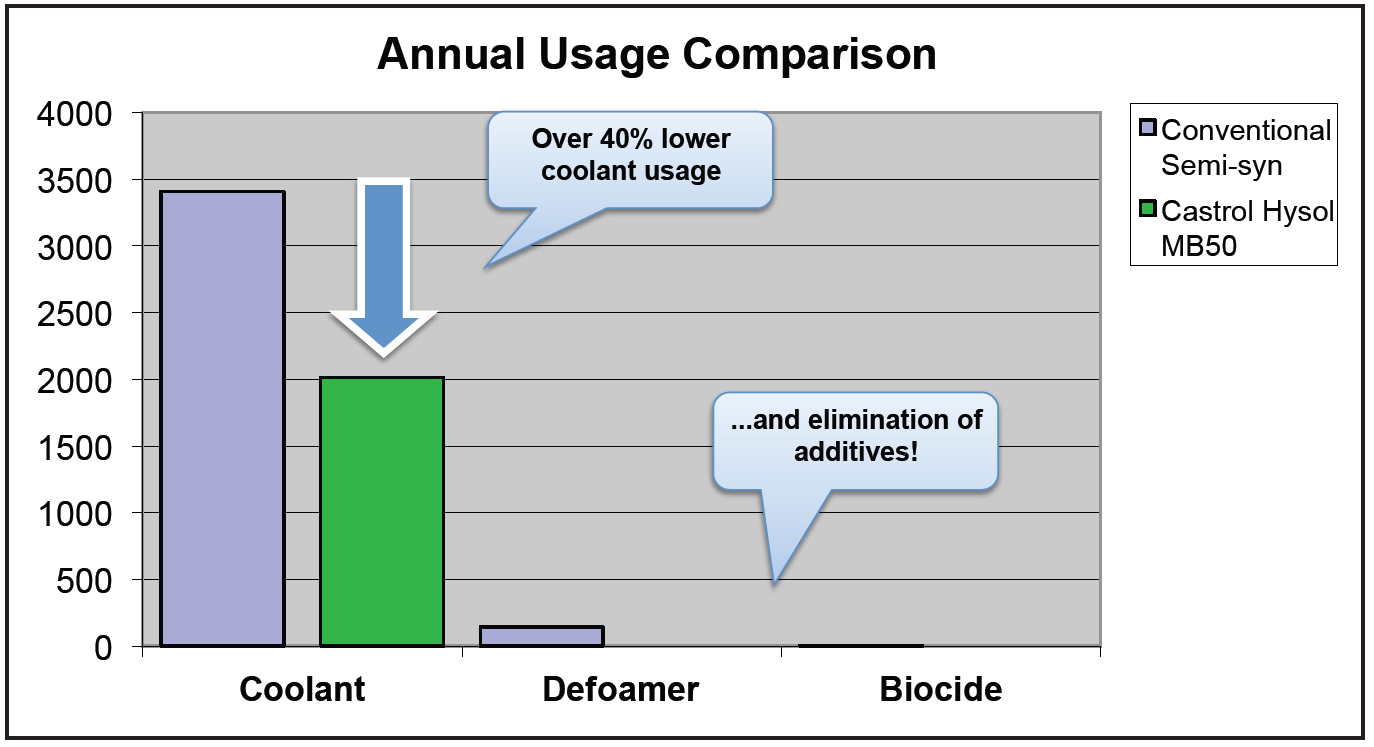

In one case study at a major agricultural engine manufacturer, Hysol MB 50 reduced the annual coolant usage by 41% and eliminated the need for defoamer and biocide additives, as shown below.

Metalworking Fluids

Synthetics

Synthetic coolants are named as such because they are completely free of mineral oils. True solution synthetic coolants consist of mixtures of polymers and other organic and inorganic materials in water. The unique technology allows for use in a wider variety of applications and metals while providing a multitude of benefits to the end user, including low usage, long sump life, excellent bio-resistance, low foam, long tool life and very clean running.

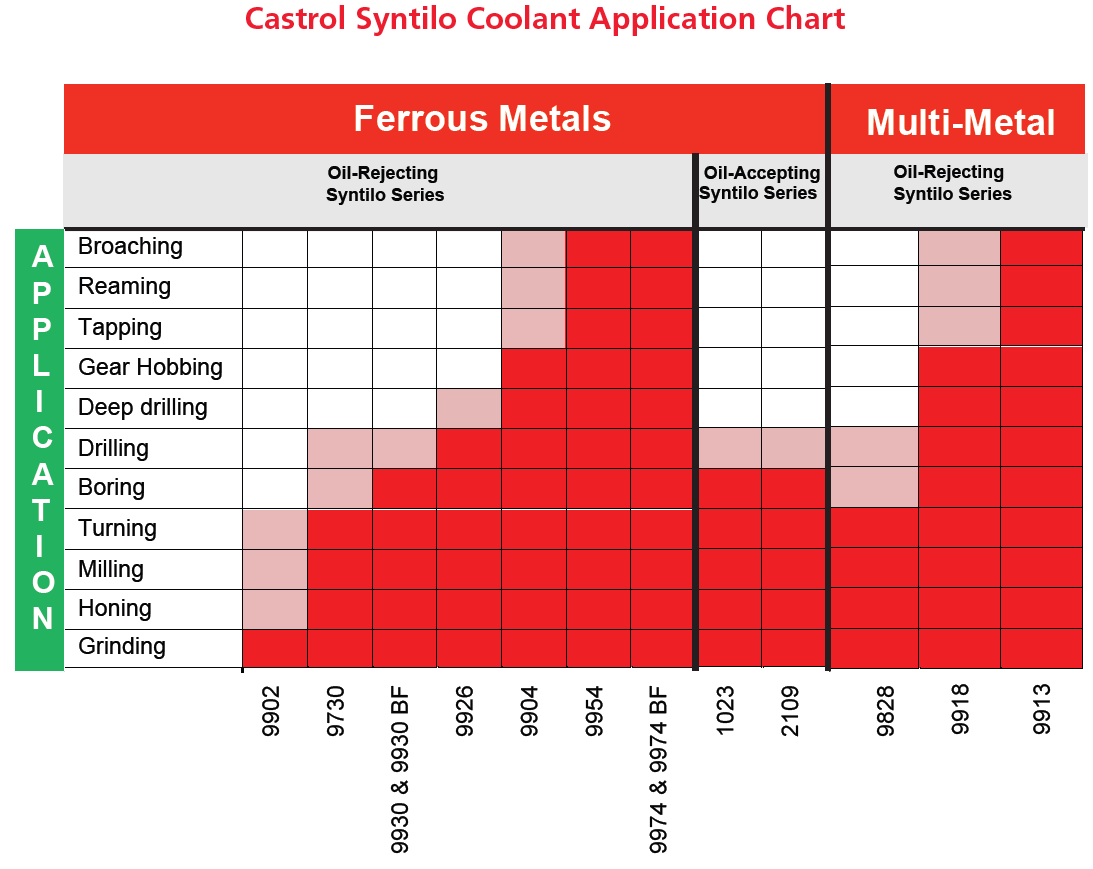

The following chart indicates recommended and possible uses for the Castrol Syntilo coolant range, including options for ferrous and multi-metal applications. Please consult your LubeCon representative for specific recommendations on machining applications and materials.

Y = Suitable –varies by application (refer to PDS) N = Not Suitable C = Consult Castrol representative prior to use

BF = boron-free fluid; note: Syntilo 9913 is also boron-free

Extremely Low Foaming

Castrol’s Syntilo brand synthetic coolants are some of the lowest foaming metalworking fluids available in the market. They are engineered to resist build-up of foam and air entrainment, even at very high pressures and short sump residence times.

Outstanding Metalworking Lubrication in Difficult Applications

The highest performing Syntilo coolants (9926, 9904, 9954, 9974, 9974 BF, 9918, and 9913) have the capability to replace neat oils in many applications due to their exceptional lubricity.

In one case study at a major automotive manufacturer, Syntilo 9918 replaced a heavy-duty neat oil in broaching piston pin holes on connecting rods. The following benefits were realized:

- Metalworking fluid usage was reduced by 70%

- Fluid carryover and contamination in subsequent processes was eliminated

- Broach bar life increased by over 45%

- Operator acceptance was increased due to improved odors

Metalworking Fluids

Cleaners

A variety of soils, particulates, residues and lubricants can remain on parts during the manufacturing process. Castrol’s specially formulated cleaners are used to aid in the removal of these soils and prepare the surface for the next process.

LubeCon offers a variety of Castrol cleaners for use depending on the needs of the process. These include alkaline oil-rejecting, alkaline oil-accepting, emulsion, solvent and maintenance cleaners. Our cleaners help resist biological growth, and many reduce energy costs because they can be used at ambient temperatures. Castrol cleaners are nitrite-free to avoid potential nitrosamine formation, which is considered potentially carcinogenic.