High-Performance Conveyor Chain Lubes

Conveyor chains provide a reliable way to transmit power, move materials or operate equipment. Chains are made of individual links with rollers (spindles), bushings and interconnecting links.

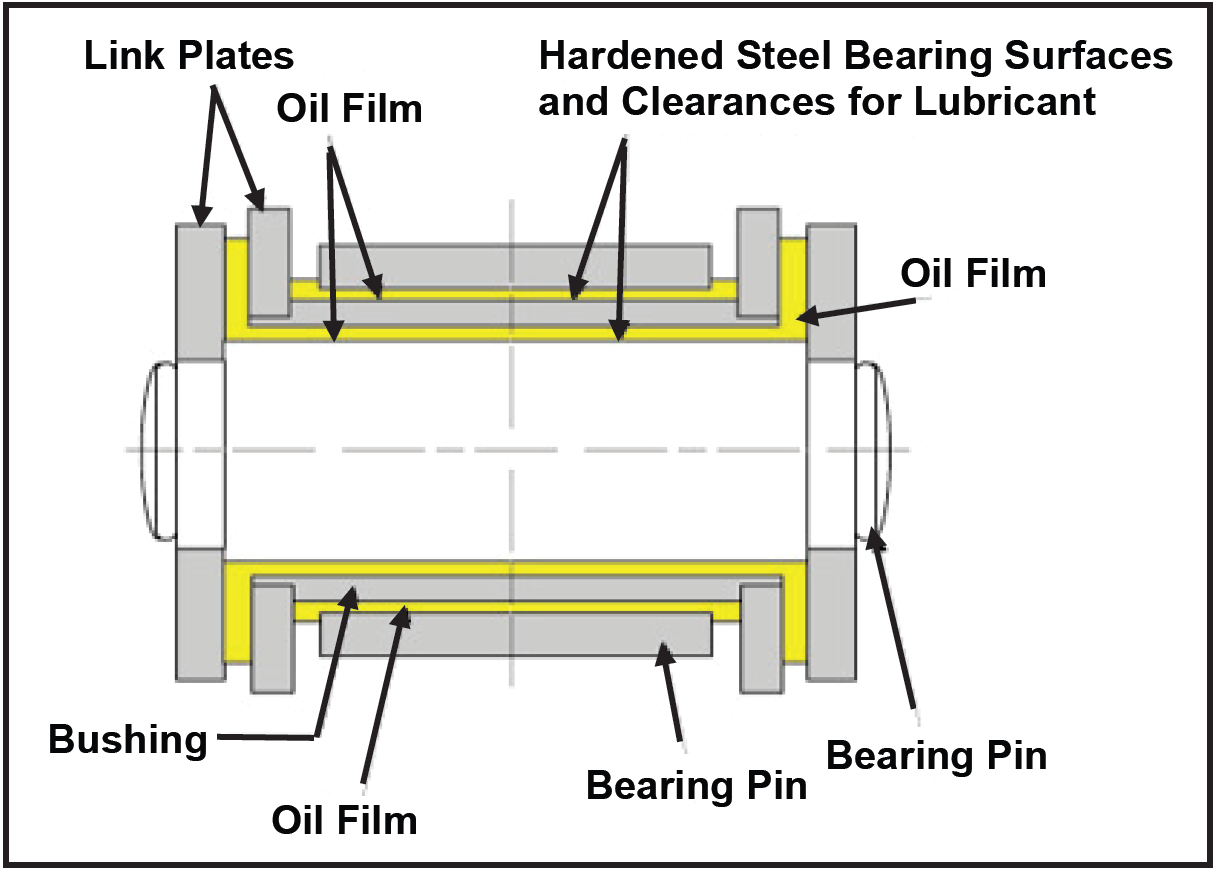

An oil film on the outside surface of a chain offers rust protection and minimizes wear at the sprocket. However, critical wear still occurs inside the chain, between each roller and its accompanying bushing.

The key to effective chain lubrication lies in penetrating the inner friction points between rollers and bushings. Picking the proper conveyor chain lube is critical to ensure penetration to the inner friction points while also handling various conditions such as high temperatures, dust, water spray and/or the need to be drip-free.

LubeCon offers a wide array of conveyor chain lubricants to meet these needs, including mineral-based oils for ambient conditions, dry-film conveyor chain lubricants to prevent drip and penetrate the chain, high temperature conveyor chain synthetic oil to maintain clean chains and provide long oil life, and food grade oils where incidental contact with food is possible.

The tight clearances of a chain link require a chain oil lubricant with excellent penetration to reach the critical inner friction points of the chain.

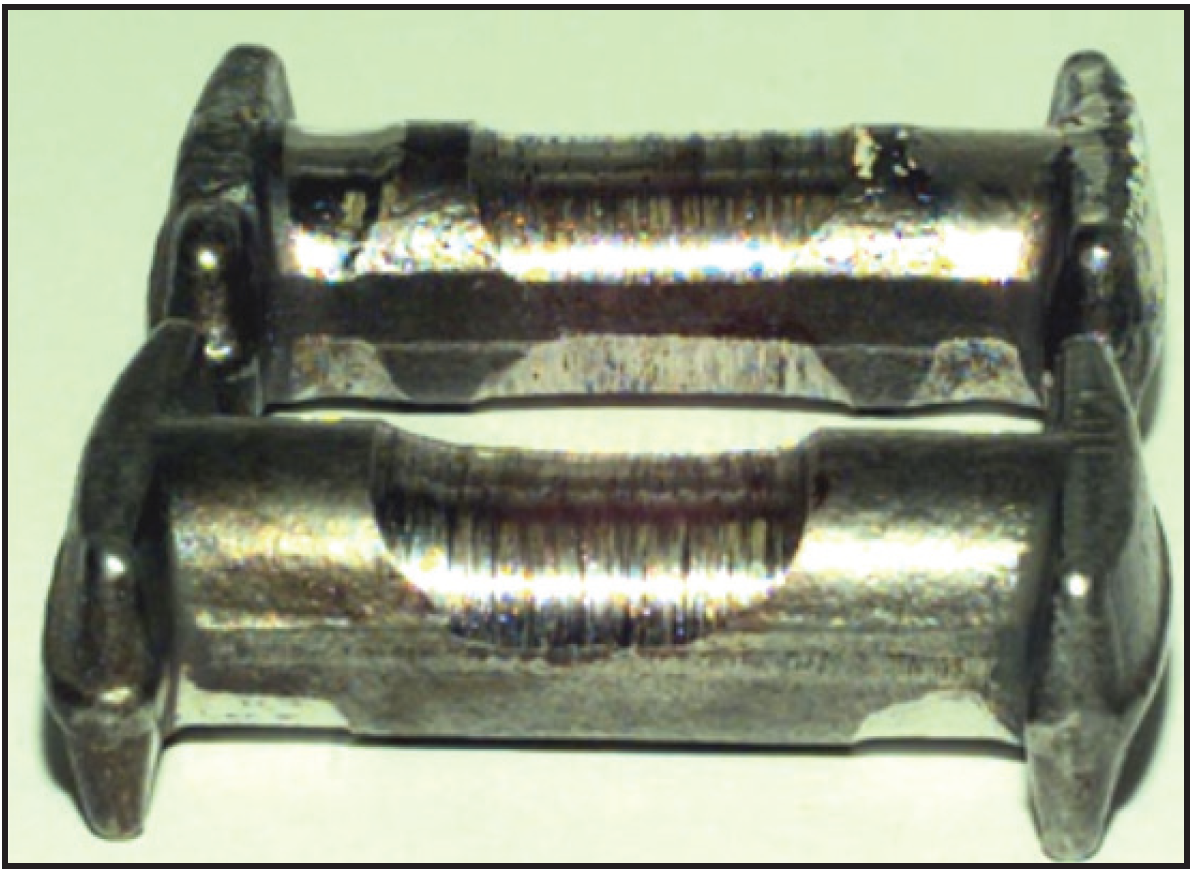

Poor penetration and lack of lubrication creates wear on pins and bushings, leading to a “chain stretch” phenomenon that requires more chain take-up over time and eventually the removal of links to shorten the chain. Using a high-quality conveyor chain lubricant can decrease chain stretch.

What Lubricant Do I Need?

LubeCon offers the best conveyor chain lubes and conveyor chain oils on the market. Click the icons below to find the lubricant type that best fits your needs.

Quick Evaporation Of Liquid Components:

Dry-Film

- LubeCon® Series I

- LubeCon® Series I/FE

- LubeCon® Series I/M

- LubeCon® Series I/M-200

- LubeCon® Series I/M O

- LubeCon® Series III/N

- LubeCon® Series O

- LubeCon® Series 301

- LubeCon® Series ATS

Synthetic

- LubeCon® HTCL

- LubeCon® Series 525

- LubeCon® Series 663 and 735

- LubeCon® Series KCL 46

- LubeCon® Series SYN HT 200

- Tribol® CH 290

- Tribol® CH 1421

- Tribol® CH 1430

- Viscogen® KL

- Viscogen® KLK

- Viscogen® G

Mineral Oil-Based

- Molub-Alloy® CH 22

Food Grade L19

- LubeCon® Series VG Light L19

- Optileb® CH L19

Increased Anti-wear Additives

Dry-Film

- LubeCon® Series I/M

- LubeCon® Series I/M-200

- LubeCon® Series 301

Synthetic

- LubeCon® HTCL

- LubeCon® Series 663 and 735

- LubeCon® Series KCL 46

- LubeCon® Series SYN HT 200

- Tribol® CH 1421

- Tribol® CH 1430

Food Grade L19

- Optileb® CH L19

Higher Flash Point

Dry-Film

- LubeCon® Series I/M-200

Synthetic

- LubeCon® HTCL

- LubeCon® Series 663 and 735

- LubeCon® Series KCL 46

- LubeCon® Series SYN HT 200

- Tribol® CH 290

- Tribol® CH 1421

- Tribol® CH 1430

Food Grade L19

- Optileb® CH L19

Lower Odor

Dry-Film

- LubeCon® Series I/M O

Food Grade L19

- Optileb® CH L19

Designed For Higher Moisture Environments

Dry-Film

- LubeCon® Series III/N

Food Grade L19

- Optileb® CH L19

Designed For Use In Food & Beverage Plants

Dry-Film

- LubeCon® Series O

Food Grade L19

- LubeCon® Series VG Light L19

- Optileb® CH L19

Compatible With Paint Lines

Dry-Film

- LubeCon® Series ATS

Synthetic

- LubeCon® Series 663 and 735

- Tribol® CH 290

Has Cleaning Characteristics

Dry-Film

- LubeCon® Series I

- LubeCon® Series I/FE

- LubeCon® Series I/M

- LubeCon® Series I/M-200

- LubeCon® Series I/M O

- LubeCon® Series III/N

- LubeCon® Series O

- LubeCon® Series 301

- LubeCon® Series ATS

Synthetic

- LubeCon® HTCL

- LubeCon® Series 525

- LubeCon® Series KCL 46

- Tribol® CH 1421

- Tribol® CH 1430

Extend Chain Life While Reducing Lube Usage

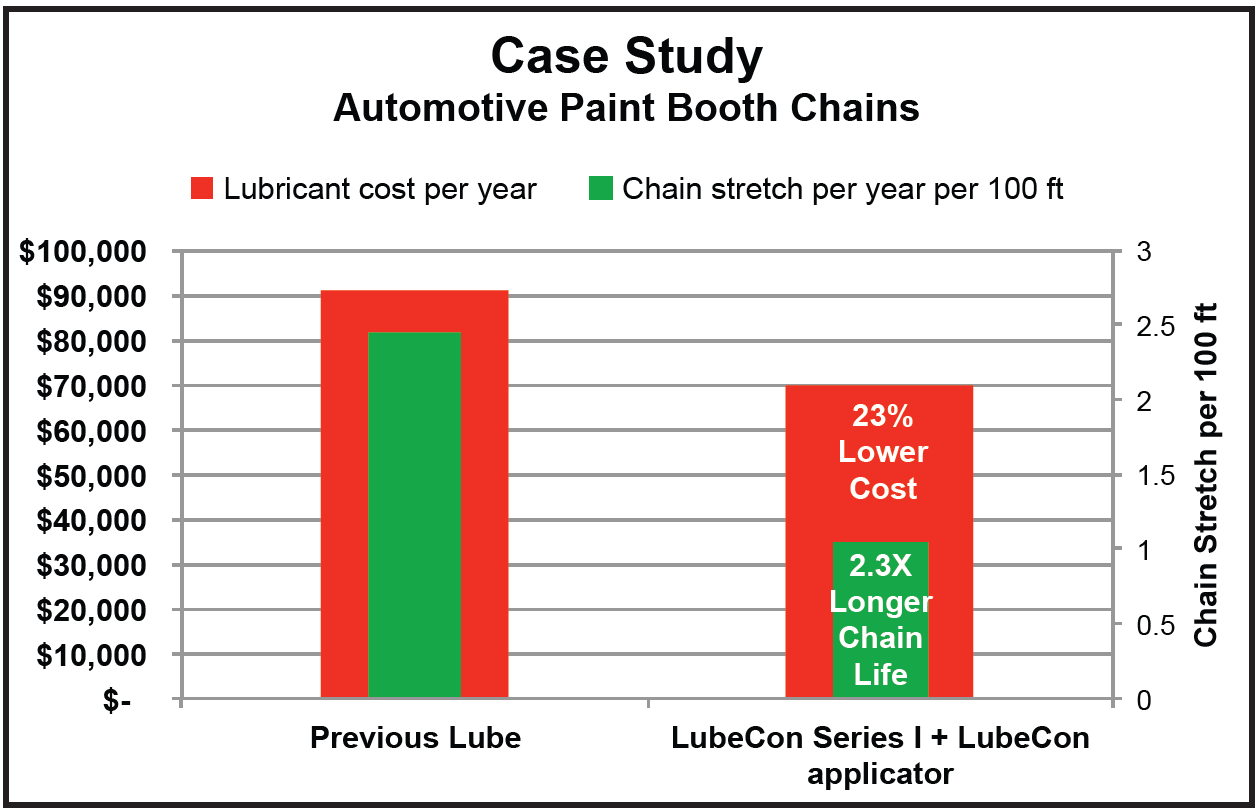

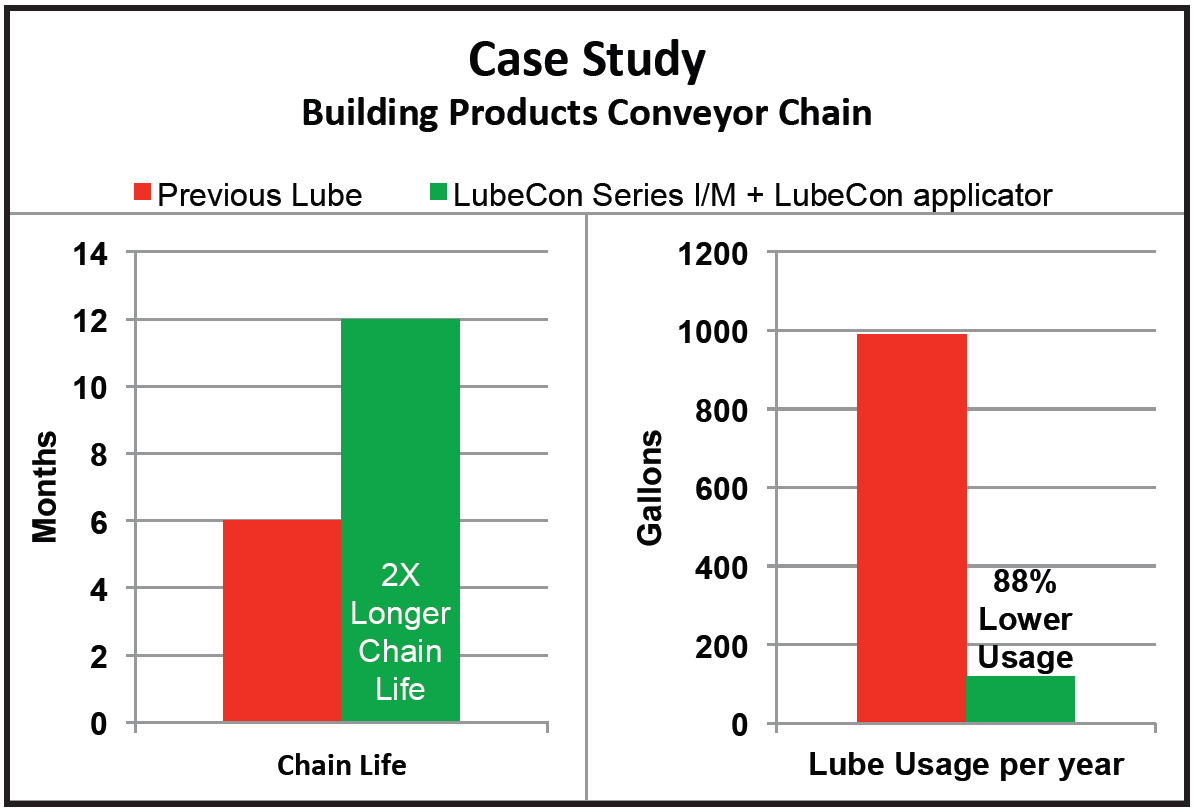

LubeCon’s combination of lubricants, applicators and service provides an optimum lubrication solution that not only greatly extends chain life but also reduces the volume and cost of lubricant.

Using less lubricant to extend chain life may seem counterintuitive; but, if applied precisely to the lubrication points of the chain, only small amounts of oil are needed for maximum effectiveness. Below are case studies that highlight just two of these many successes.

Case study from an automotive paint shop where LubeCon applicator and Series I lubricant lowered the lubricant cost by 23% while extending chain life by an estimated 2.3 times, based on lower wear rates (measured by chain stretch per 100 feet of chain).

Case study from building products manufacturer where LubeCon applicator and Series I/M lubricant lowered the lubricant usage by 88% while doubling chain life.

Chain Oil Selection Chart

| PRODUCT NAME | Type | ISO VGs Available | Viscosity Index | Flash Point | Pour Point | Data Sheets |

|---|---|---|---|---|---|---|

Mineral Based | ||||||

| Molub-Alloy CH 22 | Light viscosity, mineral based chain oil with solids | 22 | n/a | 360°F | -49°F | |

Dry-Film | ||||||

| LubeCon Series I | Heavy duty dry-film lube | 5.5 cSt | 135 | 142°F | -65°F | |

| LubeCon Series I/FE | Fast evaporating dry-film lube | 3 cSt | n/a | 109°F | -65°F | |

| LubeCon Series I/M | Dry-film lube with additional anti-wear | 5.5 cSt | n/a | 142°F | -65°F | |

| LubeCon Series I/M-200 | High flash point dry-film lube | 6 cSt | 120 | 244°F | -65°F | |

| LubeCon Series I/M O | Low odor dry-film lube | 3 cSt | n/a | 150°F | -65°F | |

| LubeCon Series III/N | Water displacing dry-film lube | 9 cSt | 135 | 150°F | -65°F | |

| LubeCon Series O | Light colored dry-film lube for food industry | 2 cSt | n/a | 150°F | -65°F | |

| LubeCon Series 301 | Moly-free dry film lube | 5 cSt | n/a | 141°F | -55°F | |

| LubeCon Series ATS | Dry-film lube for high temp applications | 2 cSt | n/a | 150°F | -65°F | |

Synthetic | ||||||

| Tribol CH 290 | Chain oil compatible with water-based paint | 150, 220 | 210 - 225 | 536°F | -49 to -38°F | |

| Tribol CH 1421 | Chain oil designed for extremely high temps | 150, 276(SG), 680 | 115 - 232 | 500°F | -46 to -20°F | |

| Tribol CH 1430 | High temp chain oil with good wetting & adhesion | 150 | 124 | 514°F | -27°F | |

| Viscogen KL 3, 15, 23, 300 | High temp synthetic chain oils | 32, 220, 250, 4000 | 107-165 | 430°F - 480°F | -76 to +1°F | |

| Viscogen KLK 25, KLK 28 | Chain oils designed for engineered wood presses | 255, 280 | 160 | 500°F | -27°F | |

| Viscogen G | High temp chain oil for glass industry | 220 | 137 | 475°F | -29°F | |

| LubeCon HTCL | Chain oil designed for extremely high temps | 46 | 131 | 445°F | -40°F | |

| LubeCon Series 525 | Chain oil designed for extremely high temps | 22 | 92 | 250°F | -40°F | |

LubeCon Series 735 | Chain oil compatible with water-based paint | 220, 22 | 185 - 225 | 410 - 565°F | -40°F | |

| LubeCon Series KCL 46 | Chain oil designed for extremely high temps | 46 | 131 | 445°F | -40°F | |

| LubeCon Series SYN HT 200 | Chain oil designed for extremely high temps | 200 | 97 | 594°F | n/a | |

Food Grade | ||||||

LubeCon Series VG Light | Semi-synthetic, H1 food grade chain oil | 15 | n/a | 226°F | n/a | |

Optileb CH | Synthetic, H1 food grade chain oil | 32, 150 | 128 - 145 | 428- 457°F | -76 to -44°F |