Chain Wear Monitors

Experience the latest innovative technology with LubeCon's Chain Wear Monitor.

Monitoring and preventing chain wear is crucial in avoiding costly downtime attributed to chain failure.

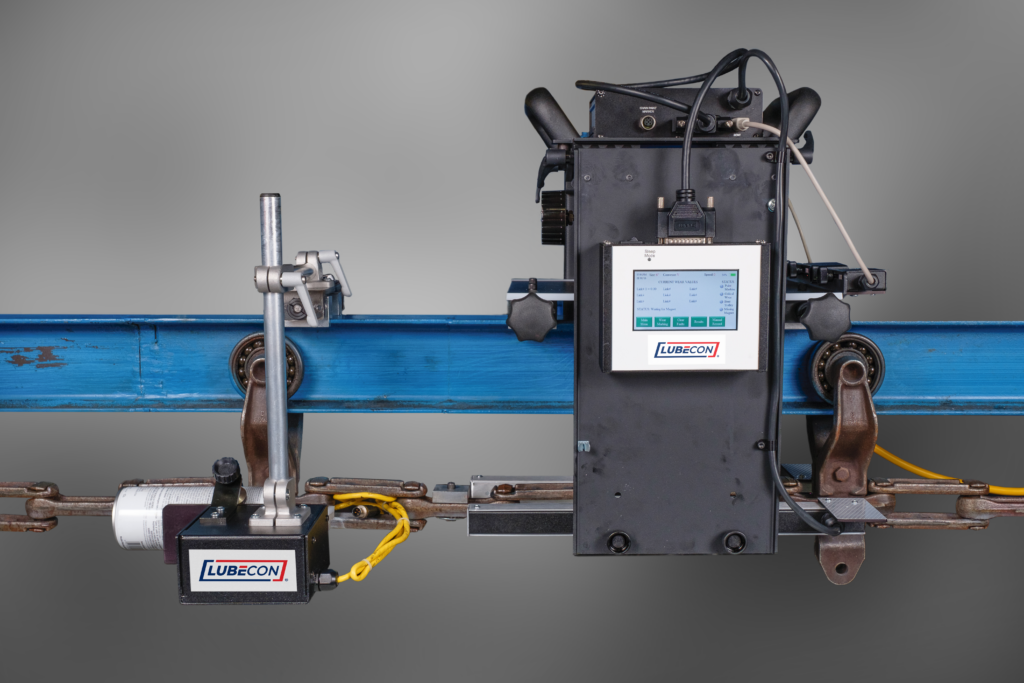

The LubeCon Chain Wear Monitor will non-intrusively measure chain wear on-the-fly. Predicting and trending wear over time, it gives you the information you need to maintain your chain. Made in the USA by LubeCon, the industry leader in chain monitoring systems and solutions.

PERMANENT

ETHERNET

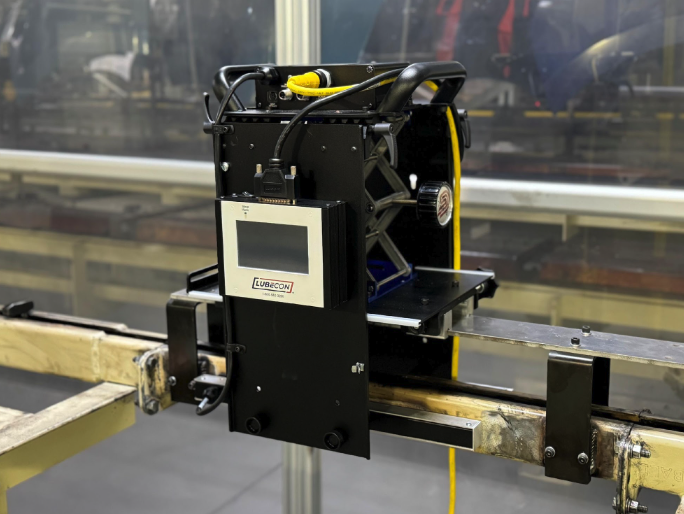

PORTABLE

USB

Portable Chain Wear Monitors allow you to move the system from conveyor to conveyor and are adaptable to most common English & Metric chain sizes. Chain wear readings are stored on the device and can easily be downloaded with the included USB memory stick. The portable model also features an internal rechargeable battery with exceptional life and quick recharge rates. A data file is maintained on the device even after battery life is diminished. The custom designed protective case is an optional accessory.

Chain wear monitoring for many conveyor types

More chains than ever are protected by LubeCon

Innovation is at the heart of our business. So, we’ve worked to cover more conveyor types than ever. These include:

- Monorail

- Enclosed Track

- CC5 or roller chains

If you have questions or want to see if your conveyor chain can work with the chain wear monitor, please contact us right away.

8x

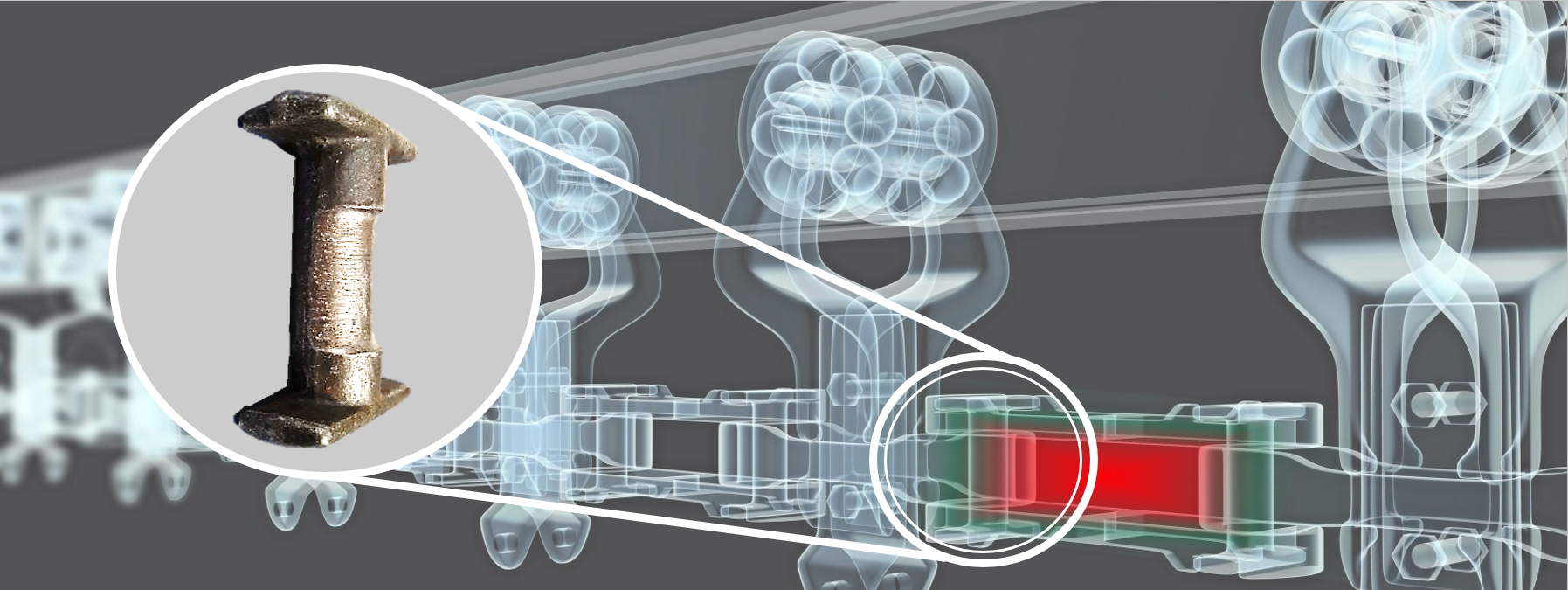

Each chain link is measured at least eight times as it goes by the chain wear monitor; the competition measures it once.

- Simple – Portable and permanent models available

- Accurate – Superior repeatability at .01” precision

- Measurement – English and Metric units available

- Power – 12+ hours normal battery life or 120-220 VAC 50/60hz

- Rugged – Built to last, with industrial components

- Convenient – LCD touch screen with information on unit

- Software – Unmatched, easy to use software experience

- Options – industry-first, Bent Trolley Detection and High Wear Marking add-ons with patented technology

- Troubleshoot – Magnet troubleshooting and system self-test available

- Diagnostics – onboard built-in diagnostics to identify current issues and anticipate needs

Data Retrieval & Software

Data Retrieval

Software Generated Reports

- Summary Report: overview of key information

- High Wear Report: easily identify link sets needing attention

- Bent Trolley Report: know the exact trolleys exceeding detection setpoints

- Wear Trend Analysis: tracks the health of the chain over time.

Add-On’s – High Wear Marking System

LubeCon’s High Wear Marker combined with a Chain Wear Monitor is an easy and effective way to mark worn chain links. The High Wear Marking add-on will accurately paint any link set that is outside of a customer set parameter.

Features & Benefits:

- Simple – Plug and play, easy installation

- Accurate – Utilizes Chain Wear Monitor wear values to determine marking

- Adjustable – High wear marking set point can be entered specific to user preference

- Battery – No additional battery or power is necessary

- Rugged – Built to last, with industrial components

- Convenient – LED indicator on device and icon on touch screen when marking

- Troubleshoot – “Test Wear Marker” verifies proper function

- Universal – Designed for standard aerosol can size

Add-On’s – Bent Trolley Detection

Features & Benefits:

- Simple – Plug and play installation

- Accurate – User specified detection range can be dialed in for your trolley

- Detection – Infrared beam technology will identify exact abnormal trolley locations

- Battery – No additional battery or power is necessary

- Rugged – Built to last, with industrial components

- Convenient – Information available on LCD screen, software report, or PLC

- Innovative – Patent Pending Technology

Chain Wear Assessment Service Available

Until recently, when manufacturers needed to assess their chain stretch, out came the tape measurer. Measuring 10-foot segments and then replacing those sections that are too long is costly in time and money.

The Better Solution

The LubeCon Chain Wear Monitor will non-intrusively measure chain wear scientifically. We’ll find the link(s) having issues so you can quickly and inexpensively fix things.

- Expectations – our service technician will bring a portable chain wear monitor; the time it takes to test depends upon the conveyor length and speed

- Reporting – data will be captured, assessed by the technician, and reports will be provided showing wear values and conveyor information