Compressor Oils

LubeCon offers a comprehensive range of world-class Castrol compressor oils and support services.

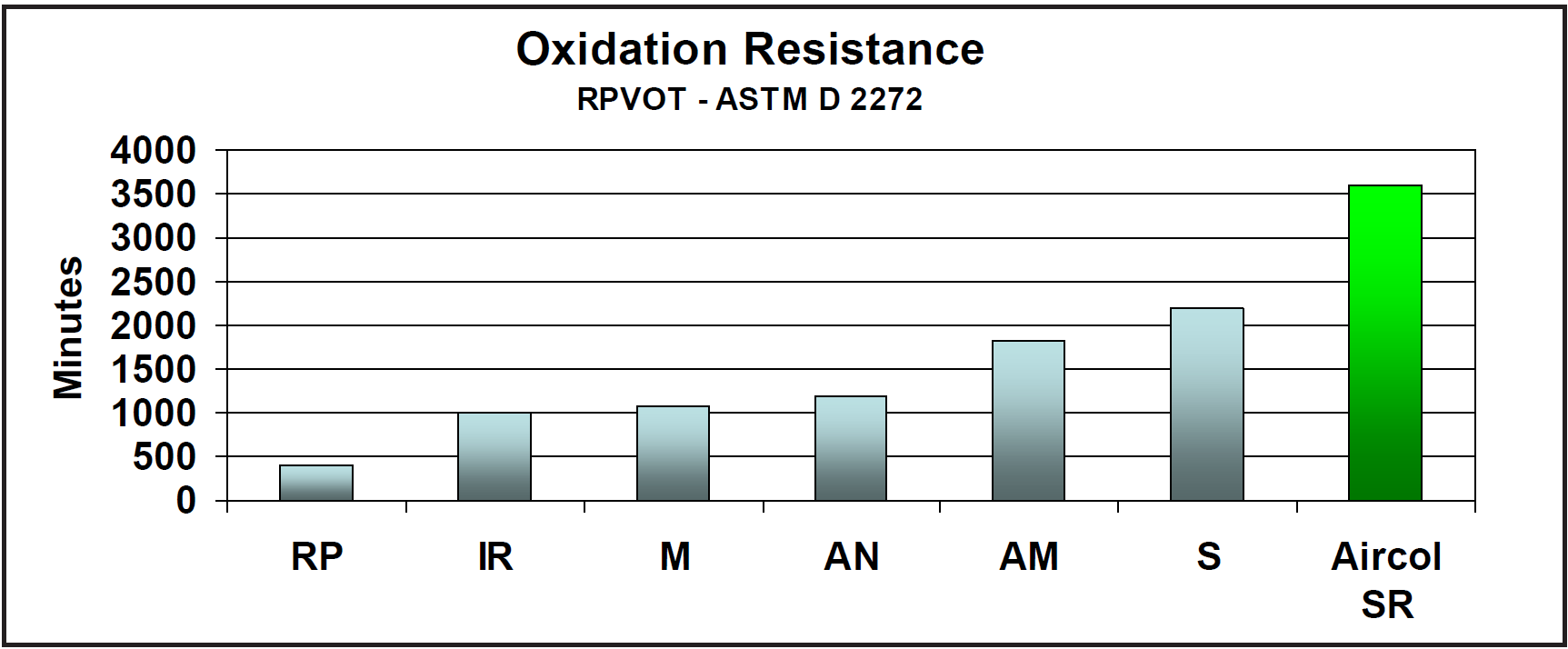

Outstanding Oxidation Resistance

Laboratory oxidation testing is a valid process for determining how long an oil will last under given conditions of heat and other catalysts that break down the fluid over time. RPVOT (Rotary Pressure Vessel Oxidation Test, ASTM D 2772) is the primary test conducted to determine the oxidation resistance of oils. In a pressure vessel, water and copper catalyst is added to the oil and pressurized with oxygen at a constant temperature of 150° C. The result is the time (in minutes) it takes for the oil to react with enough oxygen to create a 25 psi pressure drop. A long time in the test translates to better oxidation resistance.

Castrol Aircol SR synthetic compressor fluid outperforms six leading competitors in oxidation resistance test.

Compressor Oils Selection Chart

| PRODUCT NAME | ISO VGs Available | Base Oil | Additives1 | Viscosity Index | Zinc | Flash Point Range2 | Pour Point Range2 | Rotary Screw | Rotary Vane | Centrifugal | Recip - Sump | Recip - Cylinder | Vacuum Pump |

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

Mineral Oils | |||||||||||||

| Hyspin VG | 32 - 220 | Mineral | R&O | 95 | No | 410 - 469°F | -22 to +14°F | ✕ | ✕ | ✓✓ | ✓ | ✕ | ✓ |

| Tribol HM 943 | 22 - 100 | Mineral | AW | > 100 | No | 374 - 486°F | -34 to -11°F | ✓ | ✓ | ✓✓✓ | ✓✓ | ✕ | ✓✓✓ |

Semi-Synthetic | |||||||||||||

| Tribol CS 1750 | 46, 68 | Semi-Synthetic | AW | 115 | No | 490°F - 520°F | -36°F to -15°F | ✓✓ | ✓✓ | ✓✓✓ | ✓✓✓ | ✓✓ | ✓✓✓ |

Synthetic | |||||||||||||

| Aircol SR | 32, 46, 68, 100 | PAO | AW | 137 - 142 | No | 507°F - 536°F | -65°F to -51°F | ✓✓ | ✓✓ | ✓✓✓ | ✓✓ | ✓ | ✓✓ |

| Tribol CS 890 | 32, 68, 100 | Ester | AW | 61 - 152 | No | 469°F - 500°F | -60°F to -27°F | ✓✓✓ | ✓✓✓ | ✓✓✓ | ✓✓✓ | ✓✓✓ | ✓✓✓ |

1 R&O = Rust & Oxidation inhibitors AW = Anti-wear

2 Varies by viscosity grade

3 Increasing performance from 1 to 3 checks