Greasers

Putting grease in a trolley bearing can be a time consuming and difficult project for maintenance teams.

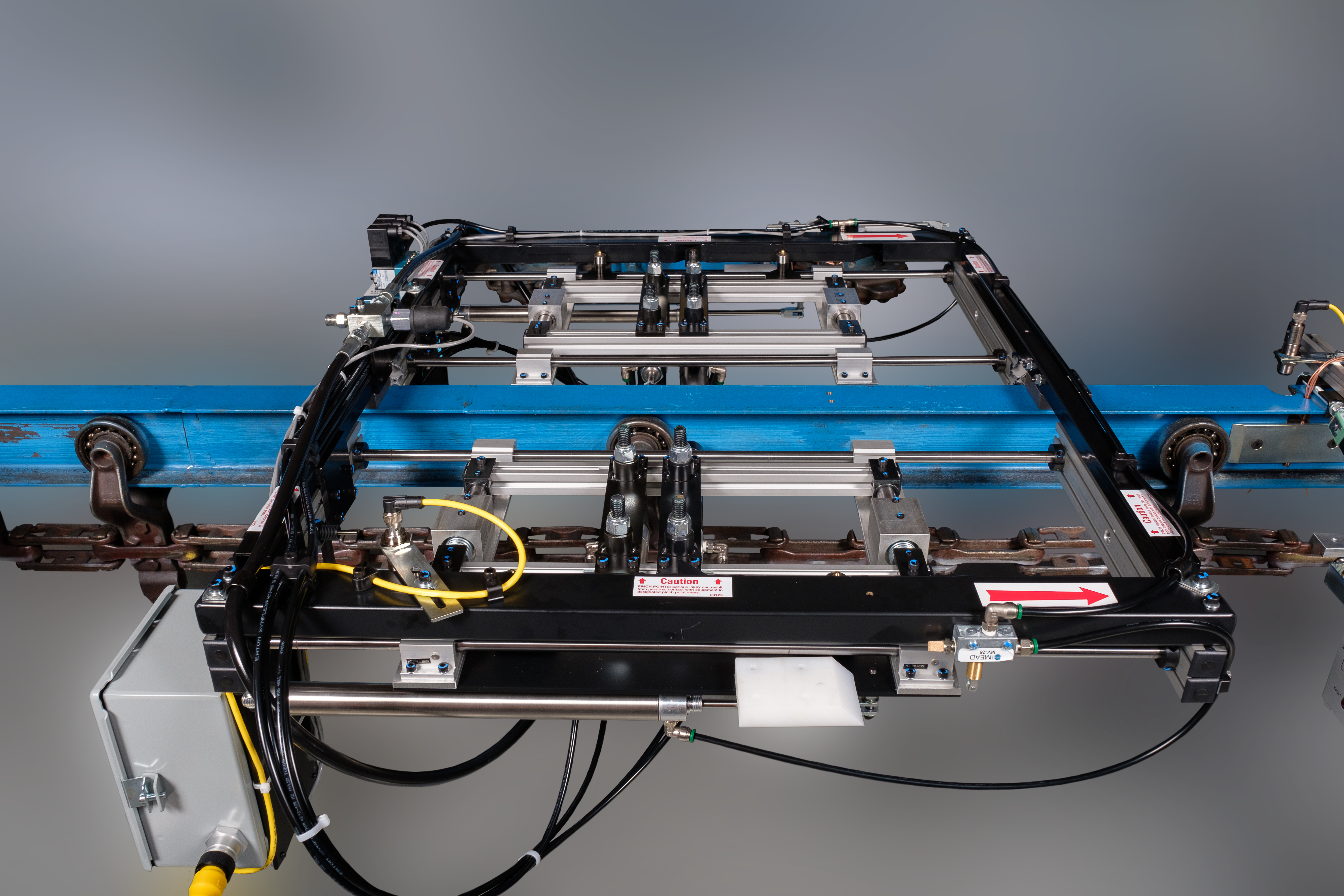

LubeCon Greasers eliminate the down-time needed to grease trolley bearings by utilizing advanced technology to automatically grease while the conveyor is running production.

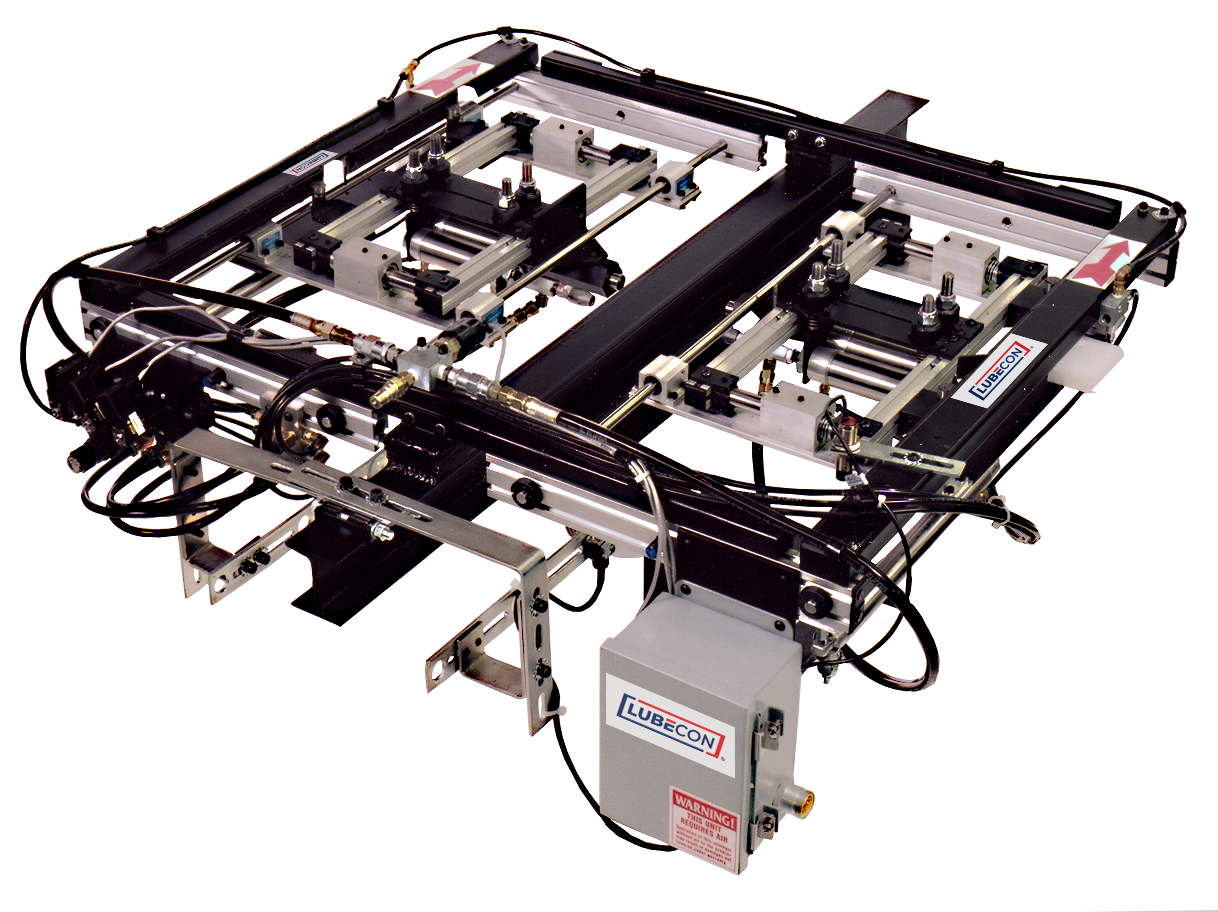

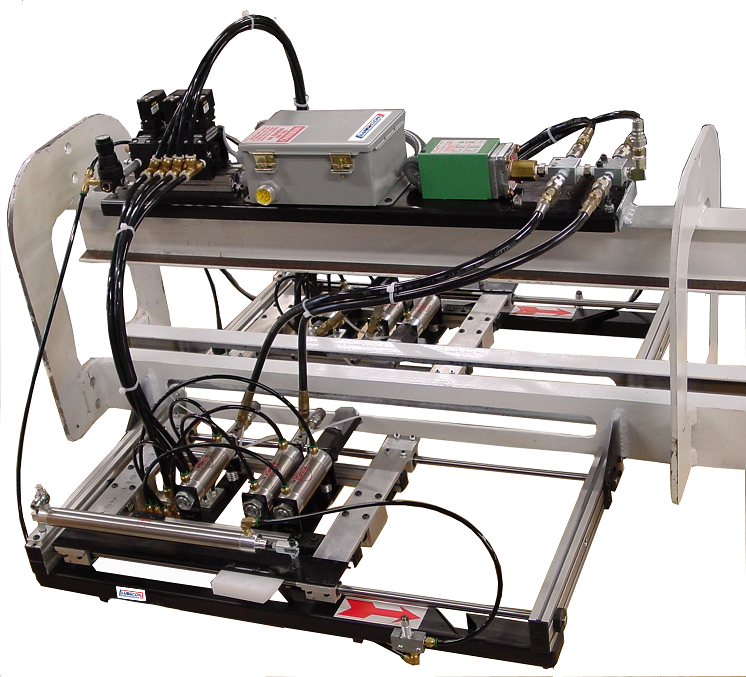

LubeCon has multiple greaser configurations to meet most industry style tracks and trolley clusters. Automatic Greasers can either be field mounted or pre-mounted with a customer supplied track to reduce installation time.

Overview:

- ASC Greaser controllers can operate one or two greaser units independently, or ASC controllers can be factory programmed to operate one grease unit and two lubricators.

- Easy menu-driven programming with a continuous display readout.

- Processor incorporates memory backup and automatic restart of lubrication if a power failure occurs.

- Push to connect wiring allows easy installation of components.

- The customer PLC interface lets you monitor your Greaser cycles along with any system faults.

- Password protection allows only qualified personnel to control greaser settings.

- All greasers incorporate a fail-safe breakaway mode which disengages the chain automatically before damage to the unit can occur.

- Greasers automatically dispense grease during the conveyor’s normal operation. (no more waiting for downtime or maintenance days to lubricate trolley wheels)

- Available greasers: Free Carrier, Inverted Free Carrier, Monorail, Inverted Monorail, Guide Wheel, King Pin, Caster Wheel, Dolly Wheel, Flat Top, Pendulum, Inverted Daifuku, and Stabilizer Greasers

Features:

- Greaser units have a user-adjustable dispense time to meet the volume needs of most sealed bearings.

- Remote located 50:1 grease pump for easy service.

- Remote located ASC controller for easy programming changes.

- Automatic shutdown for loss of power and empty grease container.

- Easy-to-read display shows a continuous readout to inform you when lubrication occurs or the time between lubrication cycles. Controllers also incorporate side-mounted LEDs that illuminate during lubrication cycles.

- Multiple controller configurations such as 120vac, 220vac, 24vdc, PLC output, machine run contacts, and beacon light allow the customer to select the right controller for the job.

Specifications:

- Safety breakaway carriage

- Empty grease container fault with automatic pump shut off

- Two independent programmable channels for greasers

- Shop air required (Min 80PSI)

- Liquid crystal display

- Oil resistant keypad

- Component fault monitoring

- Password protection

- Selective viewing of each channel

- Memory backup

- Circuitry overload protection

- Available beacon light, PLC interface, 220vac, 120vac, and 24vdc versions

Accessories:

- PLC Interface

- 120vac, 220vac, & 24vdc versions

- Watertight enclosures

- Harsh environment greasers