Greases

LubeCon offers a comprehensive range of world class Castrol greases that provide advanced protection of capital-intensive equipment. Our selection includes high-speed, high-temperature, synthetic, and moly greases to meet all your industrial lubrication needs.

Whether you require Castrol bearing grease, Castrol synthetic grease, or Castrol Tribol products, we have the optimal solution for your application. Our high-performance greases ensure reliable equipment operation, even in challenging environments, improving production efficiency and extending maintenance intervals.

Our goal is to help you achieve longer bearing life, optimize application performance, extend maintenance intervals, increase productivity, decrease maintenance costs and minimize overall grease consumption and waste.

Multi-Purpose, High-Performance Castrol Greases

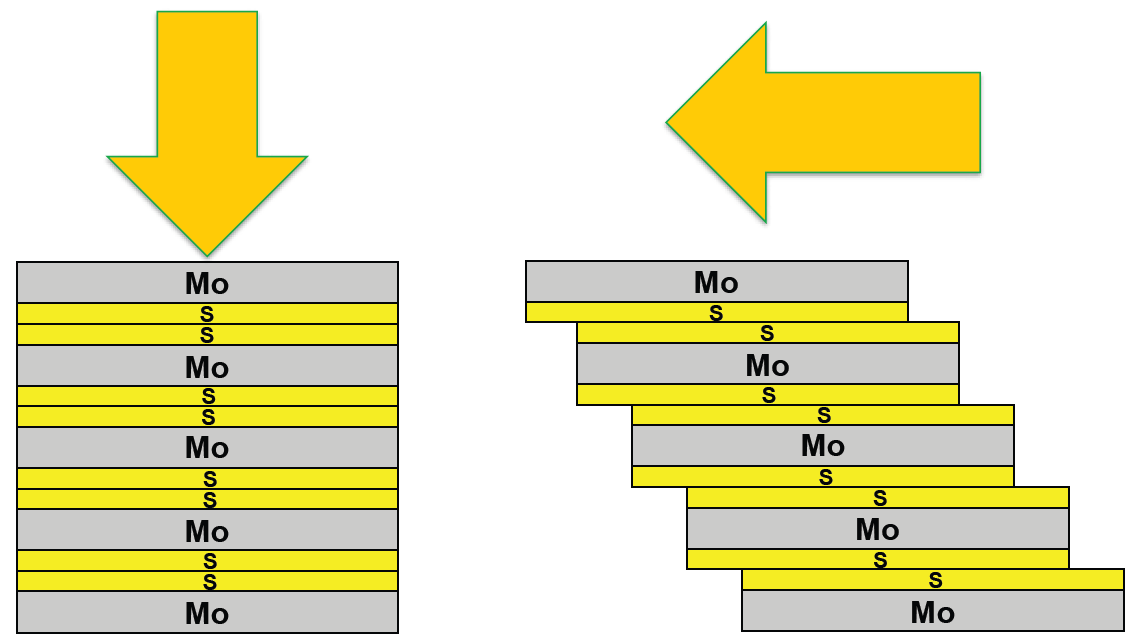

Extremely high load bearing grease capacity in this direction (250,000 psi). Sulfide layers shear easily in this direction to produce low coefficient of friction.

Castrol Moly grease is perfect for all your high load bearing grease needs. The MoS2 structure of Molybdenum Disulfide allows for extremely high load carrying capability in the perpendicular direction (250,000 psi) while shearing easily in the parallel direction to provide very low coefficient of friction to moving parts.

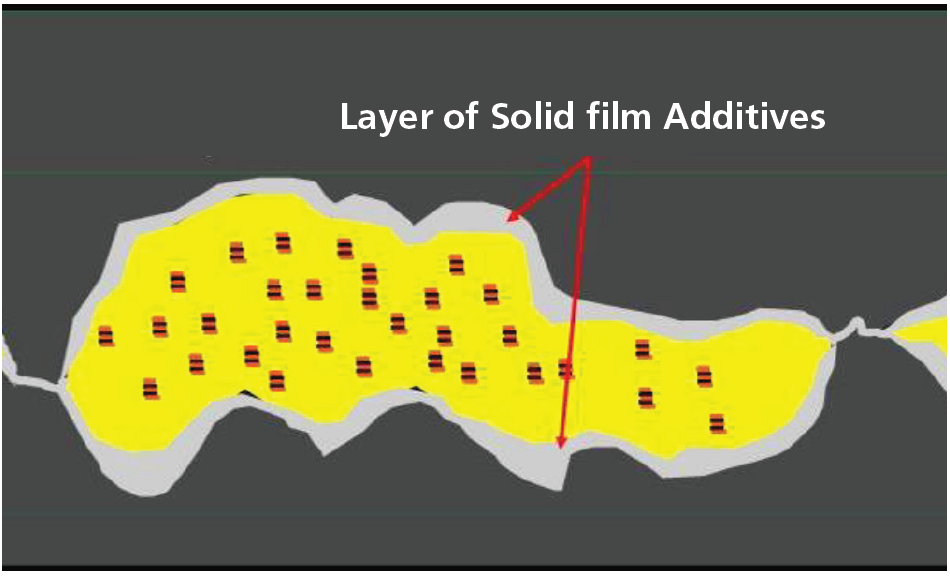

Solid lubricants are worked onto the metal surface to help prevent metal-to-metal contact.

Lubricating solids have a natural affinity for metal surfaces and provide an additional layer of protection to lower frictional forces and reduce wear rates.

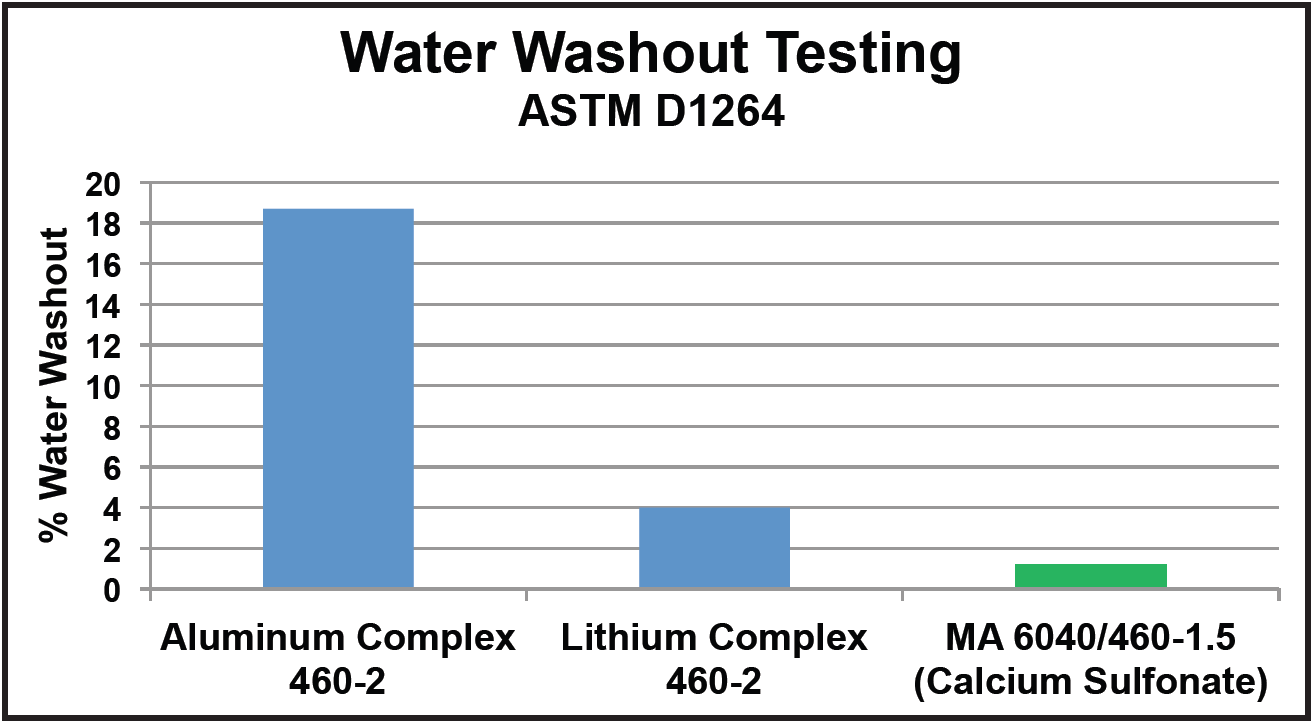

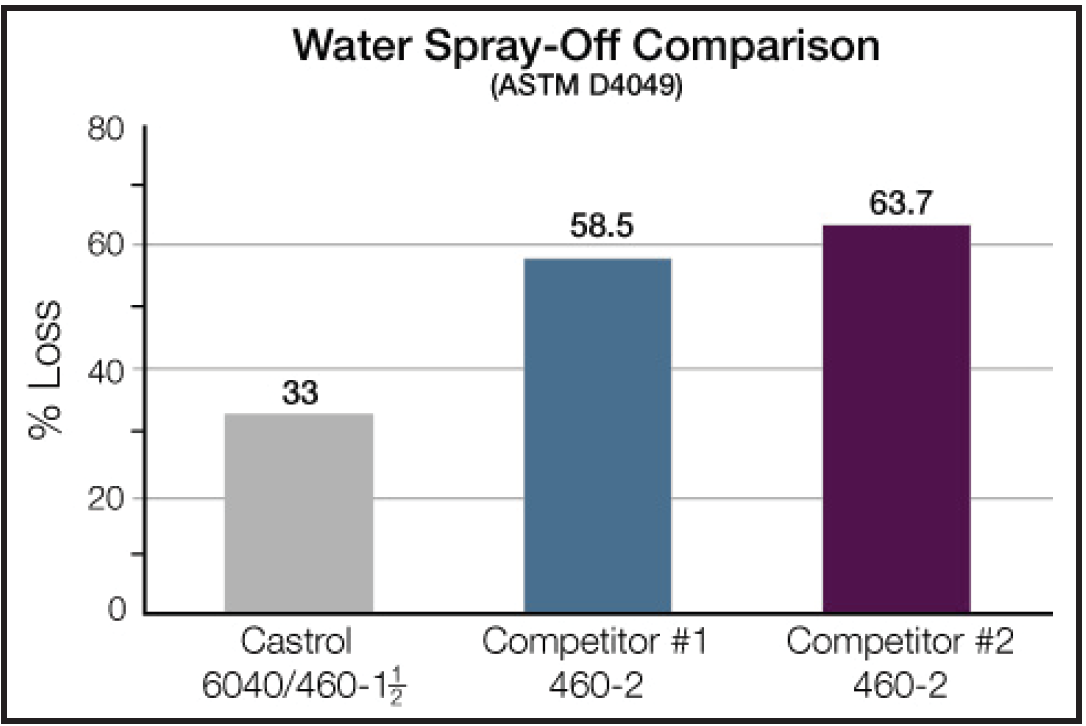

Resistant to Washout

In many applications, the washing action of water or coolant can be highly problematic and lead to poor grease retention as well as equipment corrosion and failure. Castrol greases are formulated to resist this washout effect and remain on bearing surfaces much longer, thus preventing corrosion even in the presence of aggressive process waters. The long-term benefits of Castrol bearing greases are much lower grease usage and greatly extended equipment life.

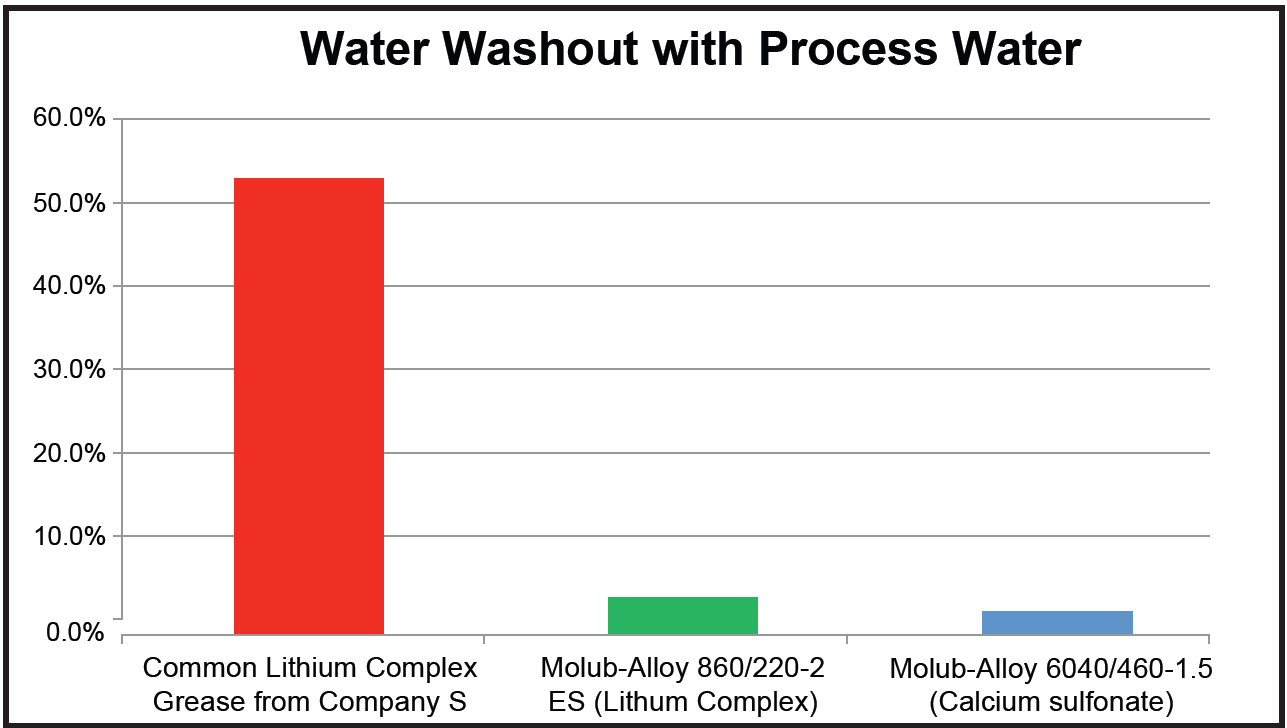

Exceptional water resistance of Castrol Molub Alloy 6040/460-1.5 compared to conventional competitors.

Water washout test results using mill water from a steel plant. Conventional greases can break down quickly in these aggressive waters, but Castrol Molub Alloy greases are formulated to withstand them.

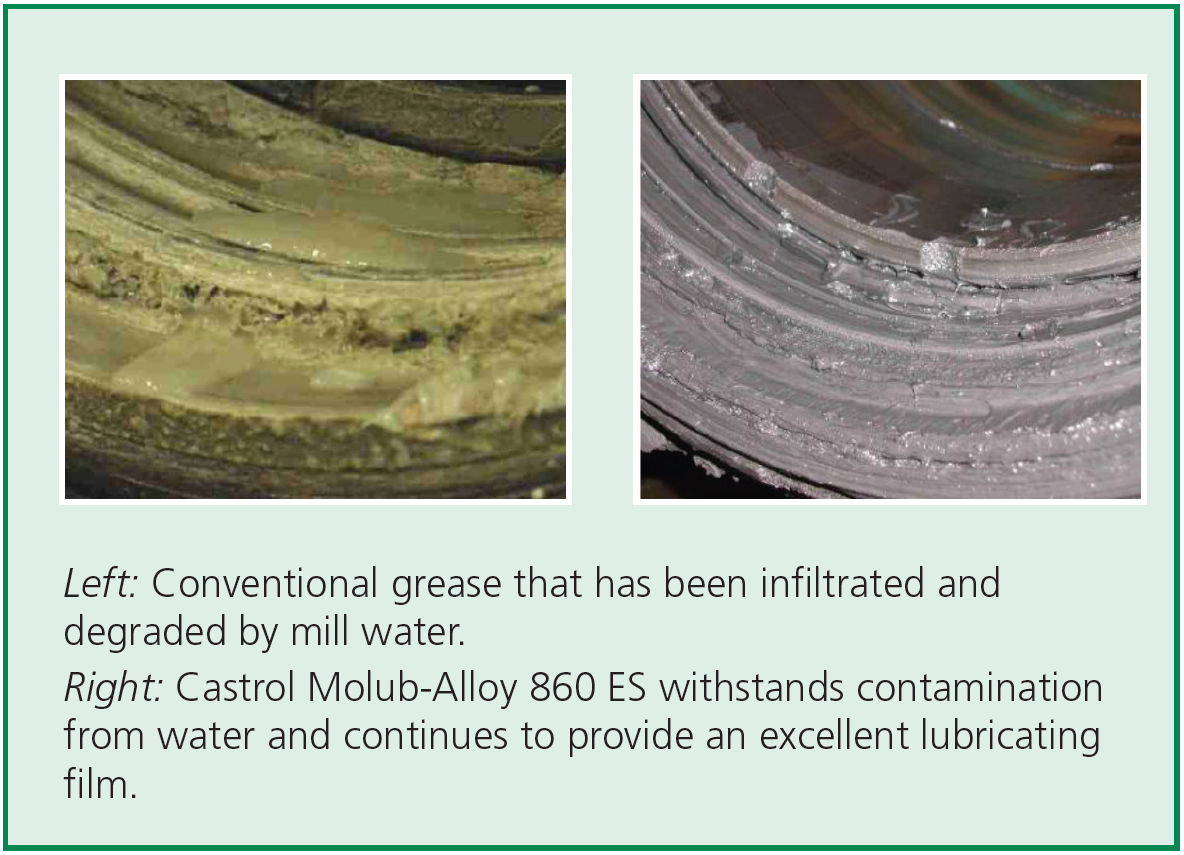

Left: Conventional grease that has been infiltrated and degraded by mill water. Right: Castrol Molub Alloy 860 ES withstands contamination from water and continues to provide an excellent lubricating film.

Grease Selection Chart

| PRODUCT NAME | Color | Thickener | Additives1 | NLGIs Available | Base Oil Type | Base Oil Vis. Available | Dropping Point (NLGI 1 & above) | Temp Range | Low Speed | Medium Speed | High Speed |

|---|---|---|---|---|---|---|---|---|---|---|---|

Multi-Purpose+ High Performance | |||||||||||

| Molub-Alloy 777 ES | Dark Gray | Lithium | EP / Solids | 1, 2 | Mineral | ISO 1000 | >356°F | +30 to +250°F | ✓ | ✓ | ✕ |

| Molub-Alloy 860 ES | Dark Gray | Lithium complex | EP / Solids | 0, 1, 2 | Mineral | ISO 150+ 220+ 460 | >500°F | +10°F to +400°F | ISO 460 | ISO 220 | ISO 150 |

| Molub-Alloy 4086 | Dark Gray | Lithium complex | EP / Solids | 1, 2 | Mineral | ISO 320+ 460 | >500°F | +10°F to +350°F | ✓ | ✓ | ✕ |

| Molub-Alloy 6040 | Tan / Amber | Calcium Sulfonate | EP | 2 (ISO 150) 1.5 (ISO 460) | Mineral | ISO 150+460 | >500°F | +20°F to +350°F | ISO 460 | ISO 460 | ISO 150 |

| Tribol GR 100 PD | Amber | Lithium | EP / MFT | 00, 0, 1, 2 | Mineral | ISO 100 | >374°F | -30°F to +285°F | ✕ | ✓ | ✓ |

| Tribol GR 1350-2.5 PD | Brown | Lithium | EP / MFT | 2.5 | Mineral | 1350 cSt | 482°F | -15°F to +280°F | ✓ | ✕ | ✕ |

| Tribol GR 4020 PD | Beige | Lithium complex | EP / TGOA | 1, 2 | Mineral | ISO 220+ 460 | 464°F | -20°F to +350°F | ISO 460 | ISO 220 | ISO 220 |

Multi-Purpose | |||||||||||

| Spheerol EPL | Amber | Lithium | EP | 0, 1, 2 | Mineral | 150 - 200 cSt | 374°F | -5°F to +200°F | ✕ | ✓ | ✓ |

| Spheerol EPLX 460 | Dark Brown | Lithium complex | EP | 1, 2 | Mineral | ISO 460 | >500°F | +10°F to +300°F | ✓ | ✓ | ✕ |

High and Low Temperature | |||||||||||

| Braycote 2115-2 | White | PTFE | Solids | 2 | PFPE | 510 cSt | None | -20°F to +480°F | ✓ | ✓ | ✕ |

| Braycote Inertox 2 | White | PTFE | Solids | 2 | PFPE | ISO 150* | None | -15°F to +500°F | ✓ | ✓ | ✕ |

| Molub-Alloy 1000 HT | Dark Gray | Organic Sodium | EP / Solids | 1 | Synthetic | 540 cSt | >500°F | +30°F to +550°F | ✓ | ✓ | ✕ |

| Tribol GR SW 1.5 | Beige | Lithium Complex | EP | 1.5 | Synthetic | ISO 460 | >500°F | -40°F to +350°F | ✓ | ✓ | ✕ |

| Tribol GR 4541 HT | Red | Lithium Complex | EP | 1 | Synthetic | ISO 150 | >500°F | -40°F to 450°F | ✓ | ✓ | ✓ |

| Molub-Alloy 6780 | Dark Gray | Lithium | EP / Solids (5% moly) | 1 | Semi-Synthetic | 130 cSt | 394°F | -40°F to +150°F | ✓ | ✓ | ✓ |

Specialty | |||||||||||

| Molub-Alloy 9030-1 | Dark Gray | Polyurea | EP / Solids | 1 | Mineral | ISO 460 | >500°F | +10°F to +350°F | ✓ | ✓ | ✕ |

| Molub-Alloy BRB 572 | Dark Gray | Lithium | EP / Solids | 2 | Mineral | ISO 150 | >356°F | -15°F to +250°F | ✕ | ✓ | ✓ |

| Optitemp LG 2 | Very light | Lithium | AW | 2 | Synthetic | ISO 46 | 428°F | -58°F to +248°F | ✕ | ✓ | ✓ |

| Optitemp PG 1.5 | Beige | Lithium complex | R&O | 1.5 | Synthetic | ISO 220 | >428°F | -40°F to +284°F | ✓ | ✓ | ✕ |

| Performance Bio GR 8899 | Yellow / Amber | Inorganic | EP | 00 | Plant-Based | 1670 cSt | n/a | +20°F to +250°F | ✓ | ✕ | ✕ |

| Tribol GR 400-3 PD | Brown | Lithium | EP / MFT | 3 | Mineral | 400 cSt | >365°F | -13°F to +284°F | ✓ | ✓ | ✕ |

| Tribol GR 3020/1000 PD | Yellow / Amber | Lithium | EP / TGOA | 0, 1 | Mineral | ISO 1000 | >350°F | -40°F to +248°F | ✓ | ✕ | ✕ |

| Tribol GR CLS 000 | Beige | Lithium / Calcium | AW | 000 | Mineral | ISO 100 | 300°F | -40°F to +212°F | ✕ | ✓ | ✓ |

Food Grade | |||||||||||

| Optileb GR 823 | White | Aluminum Complex | AW / Solids | 0, 1, 2 | White Oil | 192 cSt | >446°F | -20°F to +250°F | ✓ | ✓ | ✓ |

| Optileb GR UF | White+ Clear | Aluminum Complex | AW | 00, 1 | Synthetic | 400 cSt | >446°F | -20°F to +284°F | ✓ | ✓ | ✕ |

1 R&O = Rust & Oxidation inhibitors AW = Anti-wear EP = Extreme Pressure

1 TGOA = Tribol Gear Oil Additive, a proprietary blend of EP additives capable of improving gear condition.

1 MFT = MicroFlux Trans, a proprietary blend of EP additives capable of improving gear condition.

* Increases to 500 cSt above 100˚C temperature exposure