Powered and Non-Powered Brushes

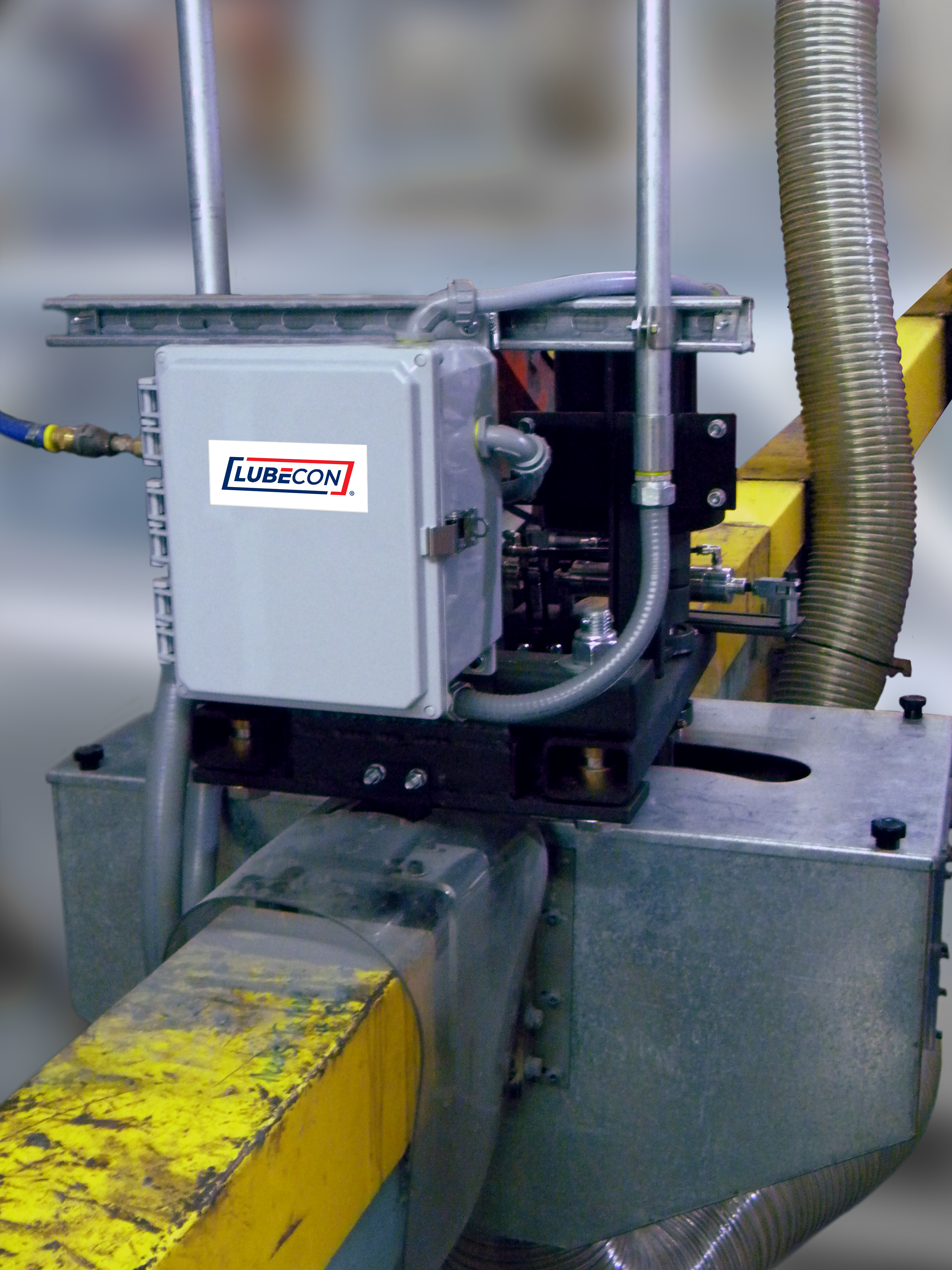

LubeCon's power and non-power brush cleaning equipment ensure that your conveyor chains and tracks are clean and free from debris.

Contamination of product from a dirty chain or rail can cause rejected parts and costly downtime. LubeCon’s heavy-duty brush cleaners are a simple solution to eliminating contamination.

Utilizing a LubeCon brush system along with LubeCon lubricants ensures your chain will be maintenance-free for many years.

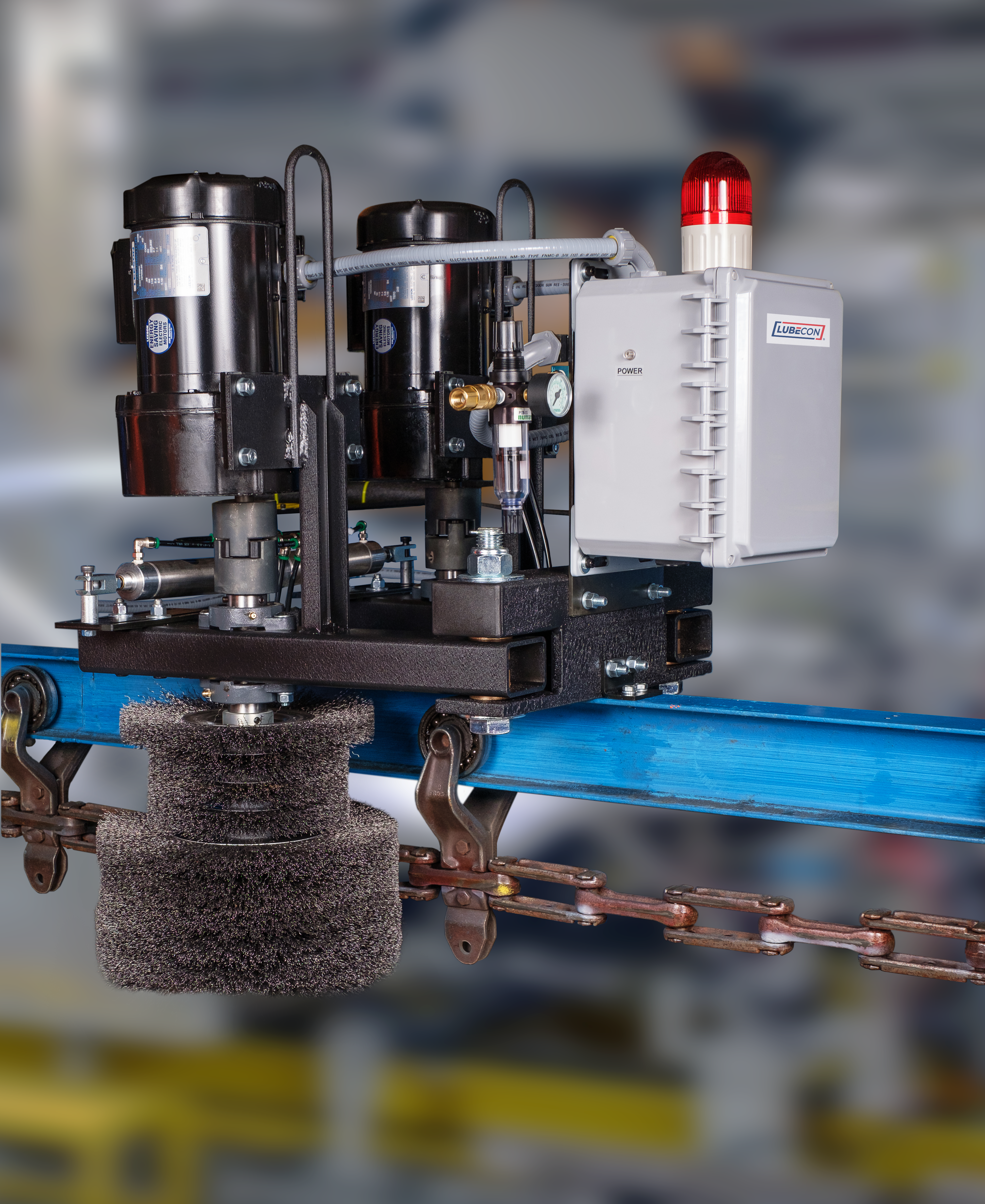

Powered Brushes:

- Dual high torque 120VAC or 220VAC motors with automatic reversing rotation to ensure proper chain/trolley cleaning and brush wear.

- Twin drive motors can take on the toughest chain debris and build up that inferior equipment can’t touch.

- Multiple controller configurations allow you to select the right brush unit for the job. Available controller configurations are as follows: 24/7 timer, countdown timer, PLC controlled, ON/OFF switch, and remotely located controllers.

- 7-second beacon and buzzer warning before system start-up. Heavy-duty debris shield surrounding brush unit.

- Power brush units are available for the following track configurations: Monorail, Inverted Monorail, C-Hook, Enclosed track, and Inverted Enclosed track.

Take Your Power Brush To the Next Level

Customers are surprised by how much debris starts falling once they start to clean their chains, rails, and trolleys. Take your Power Brush system to the next level with these essential add-ons:

- Brush covers

- High-vacuum system; literally sucks out the debris

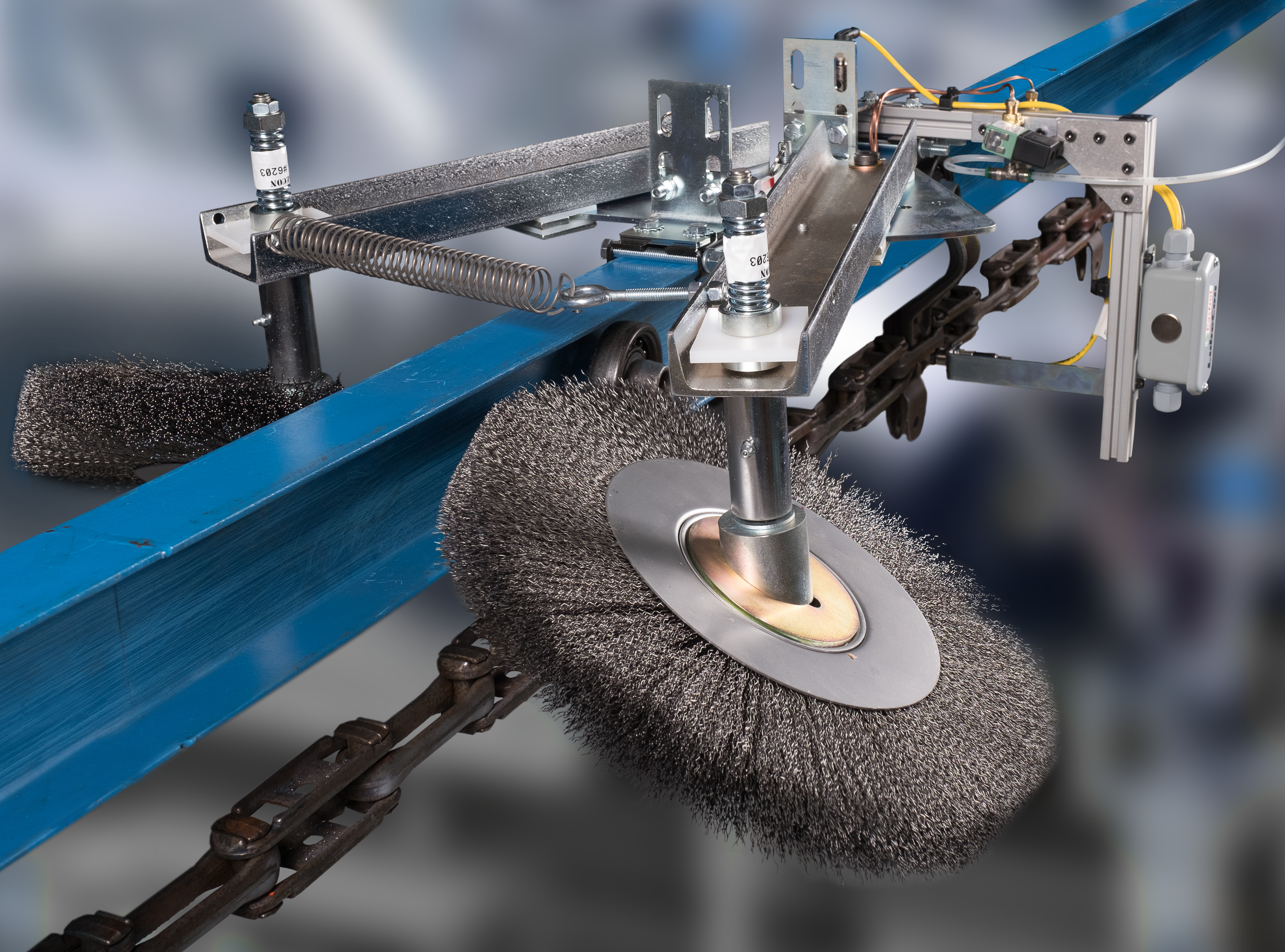

Non-Powered Brushes

- Heavy-duty 15″ brushes allow for better cleaning capabilities and better chain engagement.

- Easily adjustable drag settings for each 15″ brush helps clean even the toughest debris from conveyor chains and trolleys.

- Easy to use spring-loaded lockout pins allow the brush unit to disengage the chain until the next cleaning period.

- Non-Power brush units are available for the following track configurations: Monorail, Inverted Monorail, C-Hook, Enclosed track, and Inverted Enclosed track.

Various Brush Options

We have dozens of brush types to choose from to clean cracks and crevices in your conveyor chain line. All are made of rugged materials to manage your biggest challenges.