PM Watch: conveyor monitoring system to automatically track conveyor health

PM Watch systems simplify preventative maintenance by measuring, recording, and analyzing data about your conveyor operations and lubrication functions. PM Watch can even notify selected personnel regarding conveyor maintenance issues automatically without user intervention.

What is PM Watch conveyor monitoring system?

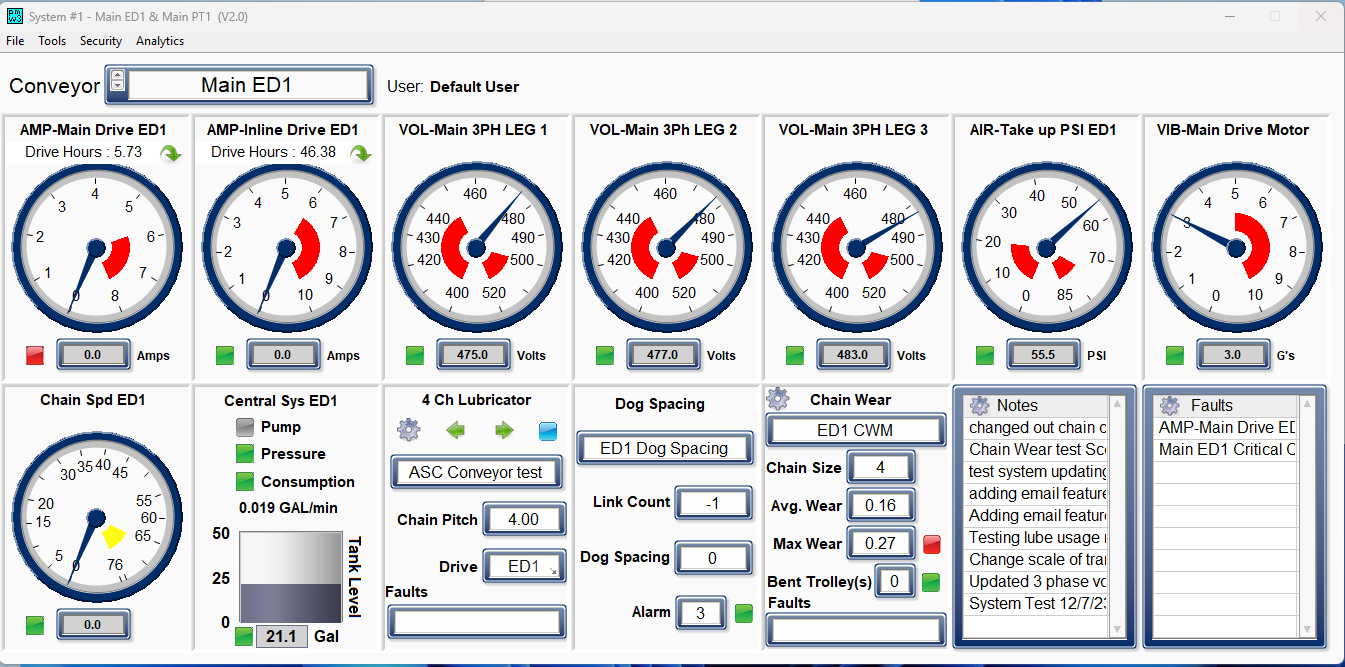

Real-time central conveyor monitoring for dozens of PM Watch systems and over a thousand transducer inputs. Track all your conveyor maintenance needs in one system with easy configuration and installation.

Each PM Watch conveyor monitoring system features:

- Central unit on the shop floor for control and reporting

- Customizable software installed at desired location for easy conveyor system monitoring, reporting, and controls

- Manage LubeCon lubrication equipment from a centralized location; monitor lubrication cycles and activate cycles if needed

- Provides retention and reporting of historical data

- Instant emailing and SMS texting for critical alarms**

- Multiple levels of software access to ensure proper controls; customizable role names

What can Our Conveyor Monitoring System Track?

- Software can monitor/control dozens of PM Watch systems. See example devices below.

- Each PM Watch system can monitor many analog and digital transducer devices; you pick and choose

- Monitored devices are plug-n-play.

Examples of devices include:

Example: Amperage transducer

Harmonics (Bearing Condition)

Air/Fluid Pressure

Voltage & Current

Temperature

Temp.

Speed

Position (Linear Distance)

Fluid Levels

Dog Spacing

Bent Trolley

Lubrication Settings

Upgraded Software - Powerful & User Friendly

Software is provided to interface and configure each PM Watch system in a network

Our conveyor monitoring software allows for:

- Real-time, live view of data from each PM Watch system in a dashboard view

- Analysis tools to interpret alarms and evaluate conveyor system data

- Configuration of connected sensors and devices

- Configuration of necessary alarm thresholds for each device

- Remotely adjust lubricating settings; trigger lube cycles

- Capture historical data and notes for future analysis

Monitor & Control  equipment.

equipment.

PM Watch can monitor most LubeCon equipment, making it easier to operate preventative maintenance equipment.

- Chain Wear Monitors: easily measure and predict future chain wear using the integrated software reports.

- Lubricators & Greasers: track oil/grease cycles and manage compatible Advanced System Controls remotely with add-on equipment and wiring

- Oil Tanks: know the tank levels and consumption trends. Set alarms for low tanks or high-lube consumption

LubeCon Chain Wear Monitor connected to a PM Watch system

PM Watch!

PM Watch!